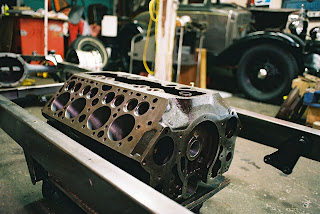

There are several things that can go wrong with your engine block while it gets older. Overall engine block repair ought to be left to the professionals as you may not have all the tools needed to carry out repairs at home. However, if you wish to tackle the problem yourself, here a few of the things that may go wrong and how you can replace them.

Required Tools

1. Full auto shop set-up

Required Materials

1. Hammer/torque wrench

2. Metal stitching kit

3. Bearings

4. Rings

5. Timing Belt

6. Chains

7. Cams

8. Lifter

Instructions

If your engine block is cracked use the hammer or torque wrench to place the metal stitch in the crack and follow the steps included in the kit to seal the crack thoroughly. Some people opt to weld the crack instead of metal stitching it however, welding is not as effective and is likely to result in problems later on. Metal stitching is a safer choice.

If you are hearing a noise and see evidence of low oil pressure the problem may be the bearings in the engine block. When replacing the bearings ensure that they fit the crank journal size. Typically the size can be seen on the backside of the bearing shell. Prior to replacing the bearings ensure that the crank is straight and does not need to be turned.

If there is black smoke coming out your tailpipe, low oil pressure or a knocking sound in the engine, the problem might be the rings. Buy the rings necessary for your specific vehicle and install them. Clean the cylinder and apply a light coating of oil to allow the pistons and rings to move freely.

Another thing that can be leading to problems in your engine block is the timing belt and chains. These items should be replaced about every 60,000 miles since age is usually what causes them to break or stretch and they may result in fatal engine problems. If your car is starting and running rough this might be a sign of problems with the timing belt and chains. You can check the timing belt by testing it with your hand to see if it is loose or broken. If you replace the chains a new crankshaft seal ought to be installed with the new chain.

If engine power is your problem the cause can be that the cams and lifters require replacing and oil is leaking into sections of the engine where it shouldn't be. When changing the cams make sure you obtain the right cam for your particular vehicle because using the wrong cam may cause the engine to overheat. You ought to replace the lifter whenever you change the cam for optimal running.

Tips and Warnings

Some metal stitching kits will tell you to put on epoxy/sealant with the metal stitching.

It is of great importance that you thoroughly lubricate the bearings prior to installing them. Installing them dry can cause them to seize up when the engine is started and this can cause additional damage to the engine.

No comments:

Post a Comment