Once upon a time, Nigeria’s textile manufacturing thrived robustly and played a crucial role in the country’s economic landscape. However, this thriving sector has faltered due to an influx of inexpensive textiles from China. Could there be hope for revival?

In the 1990s, Nigeria's textile industry was a key driver of the economy, providing employment to hundreds of thousands in Africa's most populous country.

"From Kaduna, Kano, Lagos, and Onitsha, these locations housed textile factories across Nigeria," explains Hamma Ali Kwajaffa, who leads the Nigerian Textile Manufacturers Association (NTMA).

Across the nation, textile factories generated premium materials not only for consumers in Nigeria but also for global markets. These thriving manufacturing networks additionally provided backing for nearby cotton growers.

Today, though, just a handful of factories survive, and they too are finding it tough due to the flood of inexpensive textiles coming in from overseas—especially from China.

What makes Chinese textiles cost less?

Despite having local cotton production, Nigeria’s textile producers must import dyes, chemicals, starch, and synthetic fibers from abroad.

In contrast, China's textile industry benefits from an integrated supply chain, where all the necessary goods and even machinery are available domestically.

"As China already manufactures all the necessary raw materials,” states Anibe Achimugu, president of the National Cotton Association of Nigeria (NACOTAN), “this allows them to produce goods at a lower cost.”

A significant challenge for Nigeria’s textile sector is the devaluation of the nation's currency, the naira. In 2023, under President Bola Ahmed Tinubu’s administration, policies maintaining a fixed rate for the naira were abolished, allowing its value to fluctuate based on market forces of supply and demand for foreign currencies. This change led to a decline in the naira’s worth, increasing expenses related to importing essential raw materials and components needed for production.

Could Nigerian designs be getting copied by Chinese competitors?

Hamma Ali Kwajaffa from NTMA notes that imported textiles frequently consist of polyester instead of cotton. While polyester is more affordable, it is generally regarded as being of lesser quality.

Kwajaffa states that imported textiles frequently lose their color rapidly and do not endure as much as cotton materials. Nevertheless, since certain international fabrics imitate patterns created in Nigeria, buyers might erroneously associate these with domestic producers. Additionally, garments brought illicitly from China are occasionally falsely labeled as “Made in Nigeria” and offered for less money, according to him.

Owing to its low cost, locals would opt for it regardless of potential harm to their skin and how quickly the dye fades over 2-3 days,” Kwajaffa explained to INSPIRATIONS DIGITAL. “These fake versions enter the market; they lose color fast, and people attribute this to products made in Nigeria since they’re purchasing identical designs.”

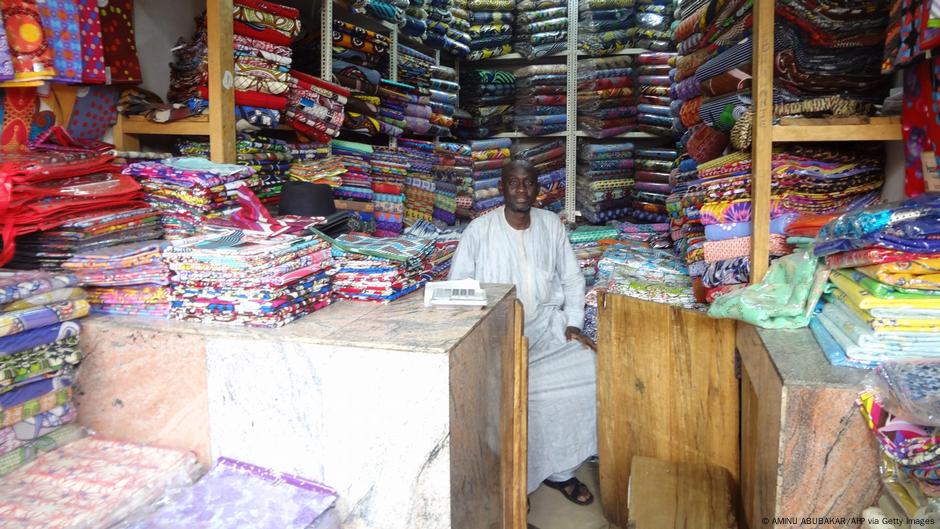

Only a few textile mills remain in Nigeria.

In 1997, the Nigerian authorities implemented the Textile Development Fund Levy Policy, which imposed a 10% duty on imported fabrics aimed at bolstering domestic manufacturing.

Over twenty years later, Kwajaffa states that this funding "has not made it to the manufacturers."

In the absence of financial backing, local manufacturers have steadily fallen behind imported goods that are less expensive. This downturn has led to job losses for millions of individuals, including those working in textiles, as well as cotton farming and trading sectors. According to industry statistics, Nigeria previously boasted more than 150 textile factories. However, data from Achimugu indicates that today, fewer than four such facilities continue to function.

The demand for domestically produced cotton keeps decreasing, and the reduction in cotton cultivation is quite evident in Nigeria.

"The 2024-25 cotton growing season has been the most challenging one I can recall," Achimugu stated.

Nigeria leaves ICAC because of outstanding payments.

Nigeria was formerly a participant in the International Cotton Advisory Committee (ICAC), which offers research, market analysis, and policy advice to bolster the worldwide cotton sector. Nonetheless, Nigeria hasn’t contributed its membership fees for many years and consequently is no longer associated with the group.

Kwajaffa thinks that the deteriorating condition of the cotton, textile, and garment (CTG) industry makes it challenging to maintain the expenses associated with being an ICAC member.

"We aren't generating sufficient profits to cover the substantial expenses. The Nigerian government could potentially utilize the Textile Development Levy to offset these costs for us," he stated to INSPIRATIONS DIGITAL.

The inconsistent availability of electric power has significantly affected the textile industry in Nigeria as well. Numerous producers depend on diesel-powered generators, thereby escalating their expenses. Consequently, this makes it increasingly difficult for domestic businesses to rival those from nations such as China, where energy supplies tend to be more dependable.

Can millions in loans assist textile manufacturers?

Last summer, the Nigerian authorities agreed to secure a loan amounting to approximately $3.5 billion (€3.2 billion) from the Pan-African Afrexim Bank aimed at revitalizing the textile sector. However, Kwajaffa expresses doubt about this approach. He likens awaiting these financial resources to the act described in Samuel Beckett’s play where one perpetually waits for someone who never arrives, implying that such initiatives often face delays or get stuck without being put into practice.

Kwajaffa stated that the representatives from the CTG sector have not viewed the loan and remain unaware of the government’s intentions regarding its utilization.

He stated, "The administration continually raises concerns about the budget, asserting that it lacks proper funding. As a result, we find ourselves constantly perplexed."

Edited by: Darko Janjevic

Author: Hauwau Mohammed

No comments:

Post a Comment